India has rapidly become a global hub for high-performance industrial machinery, especially in the fastener and metalworking sectors. Among these, Header Machine Manufacturers in India stand out for their innovation, durability, and efficiency. From compact cold forge systems to advanced automatic thread rolling units, Indian manufacturers deliver world-class solutions that cater to the growing demands of the engineering, automotive, and construction industries.

Excellence in Header Machine Manufacturing

A Header Machine Manufacturer in India is not just a producer of machines; they are the backbone of precision fastener production. These machines are designed to transform raw metal into bolts, screws, and rivets with unmatched accuracy and consistency. Indian manufacturers utilize the latest CNC and servo technologies to ensure each component is produced to international standards. Whether for small-scale workshops or large industrial setups, these machines offer flexibility, energy efficiency, and superior production speeds.

Cold Forge Header Machines in Ludhiana – The Industrial Powerhouse

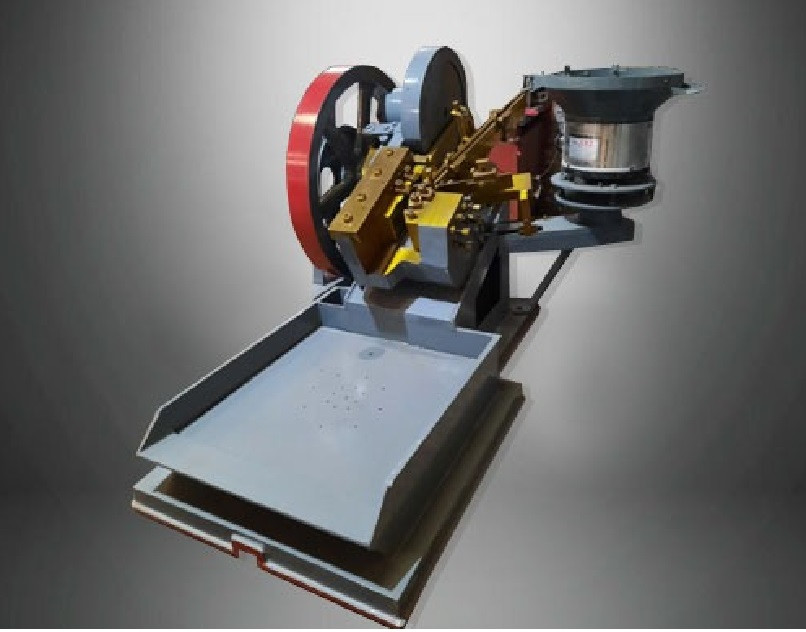

Ludhiana, known as the “Manchester of India,” is a key industrial city that houses some of the most reputed Cold Forge Header Machine Manufacturers in Ludhiana. These machines are designed for cold forming operations, where metal is shaped at room temperature without heating. The cold forging process enhances the mechanical strength and surface finish of the fasteners, making them ideal for heavy-duty applications.

Manufacturers in Ludhiana are renowned for producing machines that combine robust construction with user-friendly interfaces. Each Cold Forge Header Machine in Ludhiana is engineered to deliver precision, reduce material waste, and increase productivity. Their commitment to quality and affordability has made them trusted suppliers for both domestic and international clients.

Nut and Bolt Making Machine Manufacturers in India

The demand for high-quality fasteners has boosted the prominence of the Nut Bolt Making Machine Manufacturers in India. These machines integrate advanced forming, trimming, and threading mechanisms to produce a wide range of nuts and bolts with consistent accuracy. Manufacturers focus on durability, high-speed performance, and minimal maintenance to meet the evolving industrial requirements.

India’s nut and bolt making machines are widely used in construction, automotive, and heavy machinery industries. Their high production rates, energy efficiency, and compatibility with multiple raw materials make them a preferred choice globally.

Fully Automatic Thread Rolling Machines – Precision Redefined

In the fastener manufacturing process, threading is one of the most critical stages. The Fully Automatic Thread Rolling Machine in India is designed to perform this task with exceptional precision. These machines utilize the rolling process instead of cutting, ensuring stronger threads and extended product lifespan.

Fully automatic thread rolling machines reduce manual intervention, enhance production consistency, and improve efficiency. Indian manufacturers have successfully integrated automation, hydraulic systems, and digital controls to deliver top-notch performance that meets international standards.

Conclusion

India’s growing industrial expertise and technological advancements have positioned it as a leading source for fastener production machinery. Whether you seek a Header Machine Manufacturer in India, a Cold Forge Header Machine in Ludhiana, a Nut Bolt Making Machine Manufacturer in India, or a Fully Automatic Thread Rolling Machine in India, you can rely on Indian engineering excellence for superior performance, long-term durability, and unmatched value.

Comments