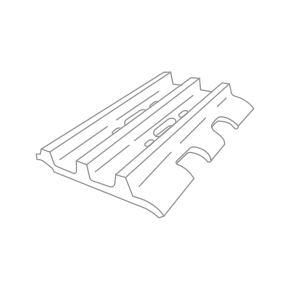

Caterpillar tracks of excavators are introduced to be utilized in one of the most difficult places. Their strong construction enables the machines to work in the mud, sand and rocky conditions without frequent breakdowns. Tracks evenly spread the weight of the machine and decreased the pressure on the ground, and minimised the slippage. This will make the operations of operators smoother and reduce downtimes during construction projects. Frequent maintenance and prompt replacement of parts that wear out performs in increasing the life of the tracks, making the excavator useful for longer periods. The process of making the right track selection is critical to cost minimization as well as efficiency in a heavy-duty project.

Importance of Case 450 Idlers

The 450 idlers are essential for the functionality of the heavy equipment. They facilitate the tension load on the tracks, and the movement of excavator tracks avoids misalignment and overwear. Good-quality idlers minimize the strain on the other parts of the undercarriage, to minimizing the expenditure on repair. In the case of construction businesses, reliable idlers will improve the performance of the machines, decrease downtimes, and ensure that projects are not delayed. Wear or damage that may occur in the idlers should also be detected early through regular inspection to ensure that the undercarriage operates smoothly and has a long life. Effective heavy machinery management is founded on proper idlers.

Using Cost-Effective Maintenance Strategies

The cleaning up of the excavator tracks and idlers does not require any elaborate and expensive process. Removing tracks when they are not in use, inspections of loose bolts and examination of idlers to determine whether they are worn are simple measures that are effective. Lubrication at the right time is a way of avoiding rust and also minimizing friction, which ensures that the machinery is operating at full capacity. The replacement parts to be used should be of quality like caterpillar excavator tracks that will make it last longer and decrease the number of replacements. These maintenance practices will be less costly in the long run and lead to better performance of a machine. Companies have enhanced operational efficiency as it minimizes operational hitches, and hence it is easier to meet strict deadlines in projects.

Upgrading the Performance of the Machines.

The refurbishment of the heavy equipment can lead to a tangible improvement in performance. The reinforcement of tracks or, even better, case 450 idlers enhances the load handling, stability and traction. The machines have improved parts and thus have a low chance of failure, thereby enhancing uptime and reliability. The enhancements also aid the operators to retain control on uneven surfaces, which enhances the safety and efficiency in the work site. Quality upgrades are a long-term investment that enables companies to finish the projects in less time and under less strain on the equipment. Better resale value comes with enhanced components in case of a replacement of machinery.

Track and Idler Environmental Adaptability.

Heavy machinery may be in various working conditions, such as soft soils to rocky grounds. The tracks of Caterpillar excavators are specially designed to respond to these conditions so that they can be used consistently. On the same note, case 450 idlers are durable and ensure tracks are stable and in line even when in demanding environments. Such flexibility enables machines to be effective in various places without having to make a lot of changes or alterations. These components can enable operators to manage various terrains and reduce the possibility of damage. The selection of the elements that work well in different environments is a practice crucial in ensuring efficiency and minimization of the stress in operations.

Purchasing Advice on Trustworthy Elements

Correct choice of tracks and idlers is the main point in order to make your machinery live. Search for components that are of known quality and that are compatible with your excavator model. Well-known suppliers should supply Caterpillar and Case 450 idlers, excavator tracks with the provision of product specifications and after-sales services. The purchasing decisions can also be informed by checking the customer reviews and talking to the experienced operators. Quality components will decrease the maintenance requirement and increase efficiency. Initially, ensuring that the correct components are invested in means that future operations will be less complicated, the equipment will last longer, and less and fewer unexpected repairs. Good research enables the achievement of the optimum value of all purchases.

Conclusion

Caterpillar tracks on the excavators and the Case 450 idlers are not pieces of equipment, but key components that enhance efficiency, stability, and performance in the heavy machinery. Putting emphasis on the durability, correct maintenance and quality upgrades of machines guarantees the smooth running of machines in different terrains. The efficiency of projects is also increased with fewer downtimes and maintenance costs associated with investing in reliable components. Track and idlers. Well-maintained tracks and idlers enhance safety and productivity, whether used in construction, in mines, or other heavy-duty tasks. In high-quality components that can be consistent and reliable, tracksnteeth.com is also a good place when in need of high-quality excavator tracks and undercarriage components.

For further info, visit our site.

Comments