When it comes to producing high-quality industrial parts, precision is key. Small variations in measurements can have a significant impact on the overall performance and functionality of the final product. This is where contract machining services come in.

The Benefits of Partnering with a Contract Machining Service

Contract machining services offer a reliable and scalable production solution for businesses looking to outsource their machining needs. By partnering with a reputable subcontract machining company, businesses can benefit from the expertise and specialized equipment required to produce precision parts consistently and efficiently.

Access to Advanced Machining Capabilities

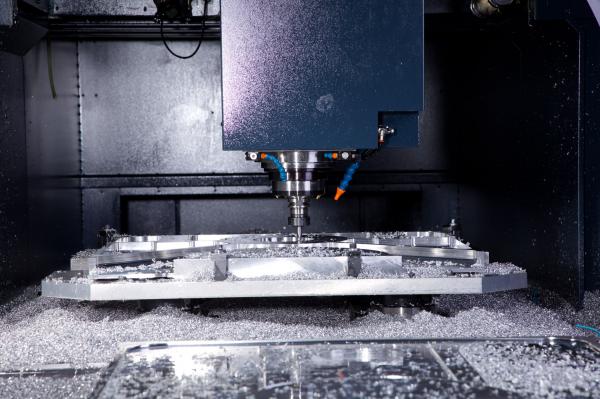

One of the key advantages of working with a contract machining service is access to a wide range of machining capabilities. These companies typically have state-of-the-art CNC machines, turning centers, and other specialized equipment that can handle a variety of materials and part sizes. This allows businesses to take on projects that may be beyond their in-house machining capabilities.

Expertise and Precision

In addition to equipment, contract machining services also provide access to skilled machinists with years of experience in the industry. These professionals have the knowledge and expertise to interpret complex blueprints and CAD designs, ensuring that each part is machined to the exact specifications required. This level of precision is essential for industries such as aerospace, automotive, and medical, where quality and consistency are paramount.

Scalability and Flexibility

Another benefit of contract machining services is the ability to quickly scale production as needed. Whether a business needs a small batch of parts for a prototype or a large production run, a contract machining company can accommodate varying production levels to meet demand. This flexibility allows businesses to focus on other aspects of their operation without having to worry about capacity constraints.

Cost Savings and Efficiency

Additionally, working with a contract machining service can help businesses reduce costs and improve efficiency. By outsourcing machining needs, businesses can avoid the high upfront costs of purchasing and maintaining expensive machining equipment. Contract machining services also have the ability to optimize production processes, reduce waste, and improve overall workflow efficiency, resulting in cost savings for the business.

Conclusion

Overall, contract machining services offer a reliable and scalable production solution for businesses looking to produce high-quality industrial parts. By partnering with a reputable subcontract machining company, businesses can benefit from access to specialized equipment, skilled machinists, and the ability to quickly scale production as needed. This partnership can help businesses improve efficiency, reduce costs, and ensure that each part is machined to the highest standards of quality and precision.

Comments