Arsenic pentoxide (As₂O₅) is a white, highly toxic compound that serves as an important intermediate in several industrial processes. It is primarily used in the production of pesticides, wood preservatives, glass manufacturing, and as a laboratory reagent. Due to its hazardous nature, its production requires specialized facilities and strict environmental compliance, making the Arsenic pentoxide production cost a key consideration for manufacturers and investors.

This article explores the major cost drivers, production methods, and market considerations related to arsenic pentoxide, along with frequently asked questions to provide clarity for stakeholders.

Introduction to Arsenic Pentoxide

Arsenic pentoxide is typically obtained by oxidizing arsenic trioxide (As₂O₃) in the presence of strong oxidizing agents, often through controlled chemical processes. Its applications include:

- Agricultural Chemicals: Used as an ingredient in herbicides, pesticides, and insecticides.

- Glass and Ceramics: Provides special properties such as improved color and strength.

- Wood Preservation: Helps in protecting timber against fungi and insects.

- Laboratory Reagent: Serves as a strong oxidizer in research and testing environments.

Given its toxic and corrosive properties, handling and manufacturing arsenic pentoxide involves extensive safety measures, which directly impact its cost structure.

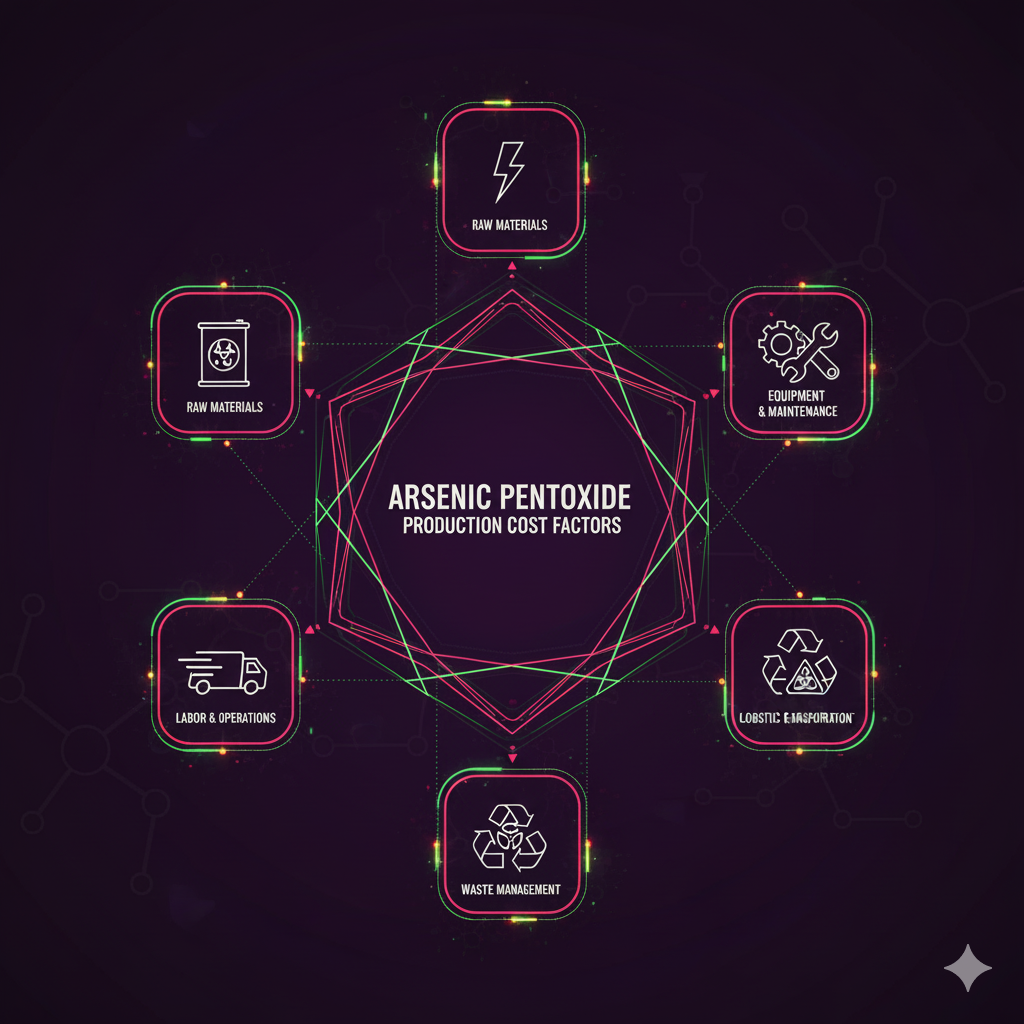

Key Factors Influencing Arsenic Pentoxide Production Cost

1. Raw Materials

The primary raw material is arsenic trioxide, obtained as a byproduct from metal smelting (especially copper, gold, and lead ores). The cost and availability of arsenic trioxide play a crucial role in determining the final production cost.

2. Production Process

Arsenic pentoxide is produced by oxidizing arsenic trioxide in an acidic medium or via high-temperature chemical reactions. Specialized reactors, oxidizers, and containment systems are required. The complexity of the process directly influences operational expenses.

3. Energy Requirements

The production involves heating and maintaining controlled reaction environments, leading to significant energy consumption. Energy efficiency measures can reduce costs considerably.

4. Labor and Expertise

Due to the hazardous nature of arsenic compounds, skilled personnel are essential. Training, protective equipment, and specialized handling procedures add to labor-related expenses.

5. Environmental and Safety Compliance

Regulatory compliance is one of the most significant cost contributors. Arsenic pentoxide production generates toxic emissions, which require:

- Advanced scrubbing systems.

- Hazardous waste management facilities.

- Continuous monitoring equipment.

- Meeting environmental standards and ensuring worker safety are non-negotiable, but they substantially increase costs.

6. Equipment and Maintenance

Corrosion-resistant equipment, sealed reactors, and high-grade containment systems are essential for production. Regular inspections, replacements, and maintenance are necessary to prevent leaks or contamination.

7. Packaging and Transportation

As a toxic material, arsenic pentoxide requires safe and compliant packaging. Transportation costs are higher than many chemicals due to specialized logistics, regulatory restrictions, and safety measures during transit.

Strategies to Optimize Arsenic Pentoxide Production Cost

- Efficient Raw Material Sourcing: Securing arsenic trioxide from reliable smelters reduces volatility.

- Energy Optimization: Using heat recovery systems and efficient oxidizers can lower energy expenses.

- Automation: Automated systems reduce direct exposure risks, minimize labor costs, and improve efficiency.

- Recycling and Recovery: Capturing and reusing arsenic compounds from industrial waste streams can cut down on raw material expenses.

- Sustainability Investments: Though initially costly, eco-friendly technologies can reduce long-term environmental compliance costs.

Market Outlook

The demand for arsenic pentoxide is closely linked to agricultural chemicals and industrial applications, though regulatory restrictions have curbed its use in certain regions. Emerging markets continue to drive limited demand, particularly in wood preservation and specialty glass. Future market dynamics will depend on stricter safety laws and the exploration of safer chemical alternatives.

Frequently Asked Questions (FAQ)

Q1: What is the main factor affecting Arsenic pentoxide production cost?

The availability and cost of arsenic trioxide feedstock is the largest determinant.

Q2: Why is environmental compliance so expensive in arsenic pentoxide production?

Because of its extreme toxicity, emissions and waste must be tightly controlled with advanced pollution control systems, which add to costs.

Q3: How does energy consumption affect cost?

Energy use in oxidation and reaction control is substantial, making energy pricing a key cost driver.

Q4: Can recycling reduce production costs?

Yes, recovering arsenic from smelter byproducts or waste streams can significantly reduce raw material expenses.

Q5: Which industries drive demand for arsenic pentoxide?

The pesticide, wood preservation, glass, and ceramics industries are the primary consumers.

Q6: How does packaging and transportation impact costs?

Due to its hazardous nature, special containers, regulatory approvals, and controlled logistics are required, increasing distribution costs.

Q7: Is demand for arsenic pentoxide growing?

Global demand is stable but limited, with growth in some niche applications offset by stricter environmental regulations in others.

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: [email protected]

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone: UK: +44 7537171117

USA: +1 307 363 1045

Asia-Pacific (APAC): +91 1203185500

Comments