In today's industrial landscape, precision and efficiency are paramount. Standard laser marking systems have emerged as indispensable tools across various sectors, delivering unparalleled accuracy and versatility. These systems are used for engraving or marking materials such as metals, plastics, ceramics, and more, making them vital in industries ranging from manufacturing to healthcare. Here's a closer look at the features, benefits, and applications of these innovative systems.

What Are Standard Laser Marking Systems?

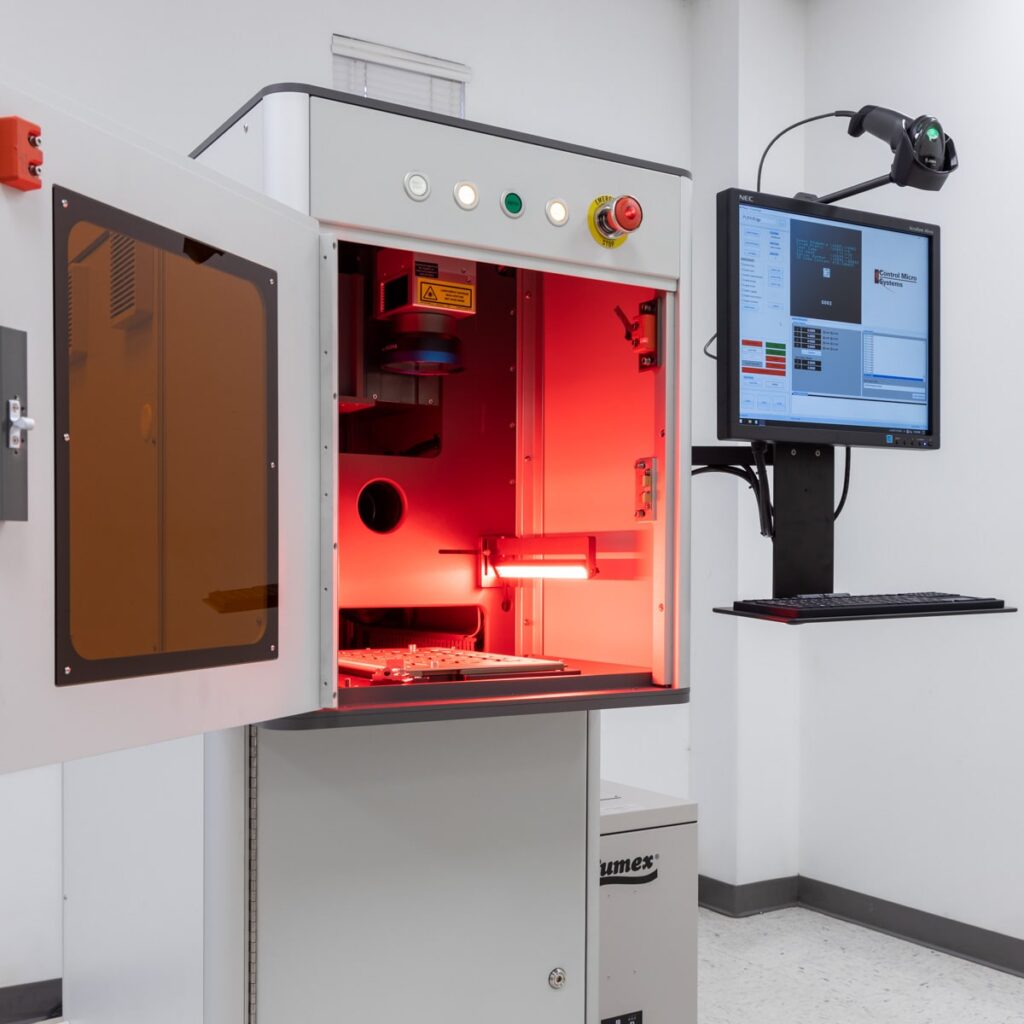

Standard laser marking systems are pre-engineered, standalone units designed to create permanent marks on a variety of materials. They utilize laser technology to etch, engrave, or mark surfaces without physical contact. These systems can produce high-resolution text, logos, barcodes, serial numbers, and other identifiers with exceptional clarity and durability.

Key Features and Benefits

- High Precision: Laser marking systems offer unmatched precision, making them ideal for applications where detail and accuracy are critical, such as micro-marking medical devices or intricate designs on consumer products.

- Versatility: These systems are compatible with a wide range of materials, including metals, plastics, glass, wood, and ceramics, offering flexibility across multiple industries.

- Durability: The marks created by laser systems are resistant to wear, heat, and chemicals, ensuring long-term readability and traceability.

- Non-Contact Process: As a non-contact technology, laser marking prevents damage to the material's surface, maintaining its structural integrity.

- Eco-Friendly Operation: Laser systems use no consumables like ink or chemicals, reducing waste and operational costs while being environmentally friendly.

- Automation Compatibility: Standard laser marking systems can easily integrate into automated production lines, boosting efficiency and productivity.

Applications of Standard Laser Marking Systems

- Manufacturing: Used for marking parts with serial numbers, barcodes, and logos to ensure traceability and branding.

- Healthcare: Essential for marking medical devices with UDI (Unique Device Identification) codes, ensuring compliance and patient safety.

- Electronics: Applied in the marking of circuit boards, connectors, and microchips for identification and assembly.

- Aerospace and Automotive: Critical for marking parts with data matrix codes, ensuring traceability and compliance with industry standards.

- Jewelry and Fashion: Used to engrave intricate designs and personalization on high-value items.

Standard laser marking systems are revolutionizing how industries approach marking and engraving. With their precision, durability, and adaptability, they are a smart investment for businesses aiming to enhance quality and efficiency. As industries continue to demand higher standards of traceability and customization, the role of laser marking systems will only grow, making them an essential component of modern production workflows.

Our website is the best source for additional information.

Comments