In recent years, the bakery industry in India has witnessed a significant transformation thanks to the introduction of cutting-edge technology. One such innovation that has taken the bakery sector by storm is the Automatic Bakery Machine India and the Automatic Bread Making Plant. These machines have revolutionized the way bakeries operate, streamlining the production process and ensuring consistency in the quality of baked goods.

The Rise of Automatic Bakery Machines in India: The traditional process of baking involves a considerable amount of manual labor, from kneading the dough to monitoring the baking process. This labor-intensive approach often leads to consistency in product quality and increased production costs. Automatic Bakery Machines have addressed these issues effectively. These machines are equipped with advanced technology that automates various stages of the baking process.

Benefits of Automatic Bakery Machines:

- Increased Efficiency:Automatic Bakery Machines significantly increase production efficiency by reducing the need for manual intervention. These machines can knead the dough, shape it into various forms, and even control the baking process with precision.

- Consistency in Quality:With automated processes, bakeries can ensure that each batch of baked goods meets the same quality standards, resulting in consistent and delicious products.

- Cost Savings:By minimizing the need for manual labor, bakeries can save on labor costs and produce more in less time, ultimately boosting their profitability.

Automatic Bread Making Plants: A Game-Changer

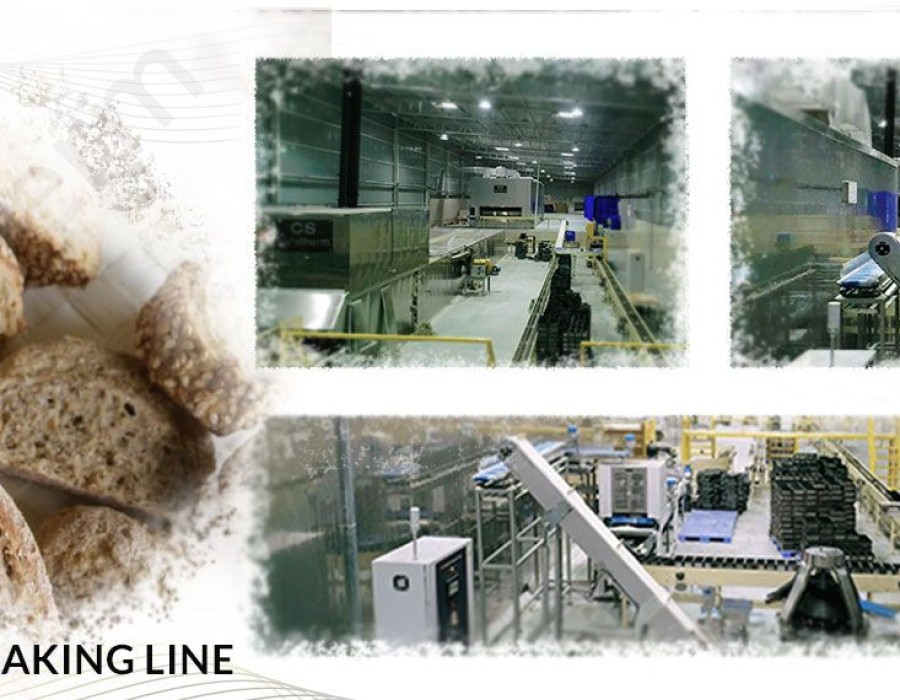

Automatic bread making plant enhance the notion of automation to a greater extent. These plants are designed to handle large-scale production of bread and other baked goods efficiently. They encompass a range of machinery and equipment that work seamlessly together to produce bread on an industrial scale.

Key Features of Automatic Bread Making Plants:

- Dough Mixing:These plants have high-capacity mixers that can prepare large quantities of dough quickly and consistently.

- Dough Shaping:Advanced machinery shapes the dough into various forms, including loaves, rolls, and buns, with precision.

- Baking and Cooling:Conveyor systems and ovens are integrated into the plant to bake and cool the bread at an optimal pace.

- Packaging:Automatic packaging systems ensure that the final products are sealed and ready for distribution.

Conclusion:

The introduction of Automatic Bakery Machines in India and Automatic Bread Making Plants has brought about a significant transformation in the bakery industry. These machines have increased efficiency, ensured consistent quality, and reduced production costs for bakeries across the country. As technology continues to advance, we can expect even more innovations that will further enhance the baking industry. If you're interested in exploring the world of Automatic Bakery Machines and Bread Making Plants, visit CSAerotherm's website at csaerotherm.com.

Comments